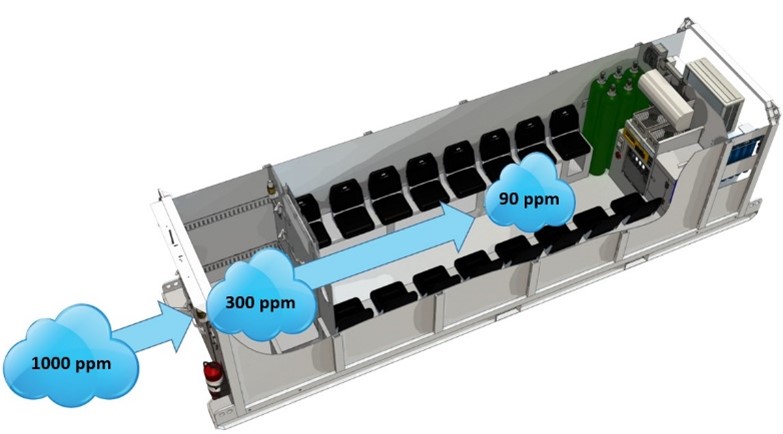

In a catastrophic event, being able to slow or stop the ingress of toxic gases is paramount to the overall functionality of the refuge chamber. Every time the door is opened for entry, the internal environment of the chamber can become compromised.

In order to mitigate this risk, a double door, airlock, or vestibule can be affixed or built into the chamber. Named differently, depending on the industry; all three systems work to achieve the same common goal – to provide passage between a potentially toxic external environment to a safe internal environment, but in different ways. Airlocks, which are commonly used in the mining industry typically have a smaller volume, thus accommodating fewer occupants than the vestibule will. Vestibules on the other hand are typically used in the petrochemical industry where a larger volume for up to ten occupants is preferred, in order to allow for the quickest entry possible.

Did you know?

The addition of a flushing airlock or vestibule to a refuge can reduce the ingress of toxic gases by as much as 90%.

System Components

Entry Way

An additional sealed entry way prior to entering the refuge is a basic requirement for any airlock or vestibule. These entry ways can either be built directly into the structure of a portable refuge or designed to be bolted on to the front of an existing refuge or bulkhead wall.

Check Valves

These one-way valves allow an internal pressure of up to 600pa to be created inside of the entry way before releasing to the external environment.

Compressed Air

Generally available either by compressors or cylinders stored in the entry way, compressed air is a vital component for the airlock or vestibule to be able to flush or pressurize as required.

Access More Resources

System Operation

Double Door Entry Systems

Double door entry systems are the simplest of the three systems and feature a passive entry way at the front of the refuge which is not pressurised. This system operates by simply using the doors as a barrier to entry. The size and shape of the door along with the volume of the airlock will determine the final concentration inside the refuge chamber (i.e., the faster the door can be opened and closed the lesser the number of contaminants that can enter the airlock). A standard MineARC door has an ingress factor (i.e., multiplier coefficient) of 0.3 for contamination upon entry.

Airlock Systems

Airlocks utilise compressed air as a primary means of flushing after entry, in order to purge the airlock. In the event of a compressed air failure or the lines becoming compromised, a back-up flushing system (BFS) is operated by pushing and holding a blue button inside of the airlock to release compressed air from cylinders, flushing the airlock. MineARC’s MineSAFE Refuge Chambers are supplied with enough compressed air cylinders to perform two volumetric flushes per entry. Effectively reducing the internal concentration inside the airlock by a quarter.

Vestibule Systems

Refuges located on the surface typically use a vestibule instead of an airlock. This is due to the requirement to get people inside the refuge as quickly as possible along with the fact that air compressors on the surface would likely draw contaminated air into the chamber. Vestibules are therefore designed to utilize only compressed air cylinders to create a positive pressure inside of the vestibule prior to entry. Creating this positive pressure requires far less air than purging the entire volume. The system is operated by pressing a blue button on the outside of the vestibule, which releases compressed air for a predetermined time in order to create the positive pressure. The flushing time is adjusted by MineARC based on the time it takes to get each group of persons though the vestibule and inside the chamber.