Every refuge chamber requires an emergency power source to maintain the life-sustaining equipment if mains power fails. An uninterruptible power supply (UPS) for refuge chambers differs from backup generators in that it provides almost instantaneous protection from power interruptions.

How can you ensure the performance and longevity of refuge chamber batteries and an uninterruptible power supply underground?

This Tech Topic explains Satellite UPS’s fundamental mechanisms and how this product makes a difference to your batteries’ health.

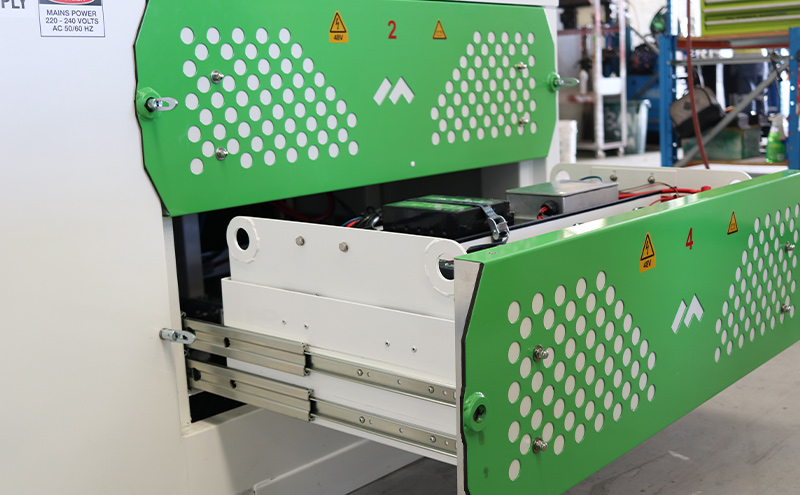

Portable Refuge Chamber Battery Banks

The MineARC Satellite UPS System (SUPS) is a unique, portable battery bank, removing the need for integrated battery and inverter storage at the rear of the refuge chamber. The Satellite UPS System’s significant features include safer battery handling during replacement, charge balancing, temperature cooling, and improved battery monitoring and diagnostics through MineARC’s GuardIAN Refuge Chamber Monitoring.

The three unique features that extend the battery systems’ life include cooling, balancing, and monitoring.

Satellite UPS Temperature Control

As heat significantly impacts a battery’s life, active cooling systems are required to combat harsh atmospheric conditions.

About battery management, temperatures above 25°C are considered high. Anything above this mark will cause excessive stress on the batteries, resulting in battery power depletion over a shorter period. A battery’s life will decrease by half with every 10°C increase in temperature – and this damage is irreversible.

The hotter the battery, the faster chemical reactions will occur; often resulting in damage to the battery’s internal structure due to fluid evaporation.

Battery Cooling Solutions

- Artificial Cooling: An internal air conditioner within SUPS provides consistent cooling

- Dissipation of Heat Generated: SUPS design maximises the natural process of heat flow caused by battery convection, conduction and radiation

- Monitoring: SUPS protects against overheating by proactively managing and monitoring heat distribution

Battery Balancing

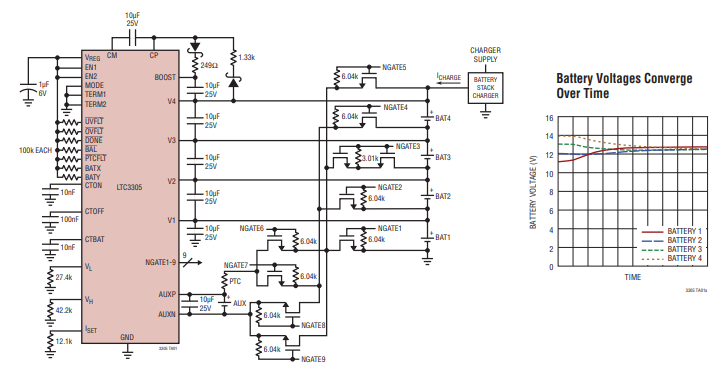

Charge balancing involves ensuring the even distribution of energy among each cell in a string of batteries. Without balance, a portion of the power within the battery is wasted.

Within SUPS, cells are sorted by the state of charge (SoC) and control charging, with compensation for temperature in strings appropriate to system voltage (48V or 24V – 4 x 12V battery strings).

Battery balancing across the strings is achieved by utilising Linear Technology, LTC3305, as shown in the diagram. This standalone lead-acid battery balancer can support up to four cells, using a fifth reservoir battery cell (AUX). The AUX cell continuously places itself parallel with each cell, to balance all of the battery cells.

The balancer ensures each cell is charged equally by absorbing charge from higher voltage batteries and transferring that charge to lower-voltage batteries. This transfer extends the cell cycle life and provides an added layer of protection by counteracting damage due to deep discharging rather than overcharging.

Monitoring Refuge Chamber Batteries

Through MineARC’s GuardIAN Refuge Chamber Monitoring, faults within a battery stack can be quickly identified and appropriate action taken to reduce a poor performing battery’s adverse effects. Changes in battery condition and performance communicated to the control room in real-time allow for data analysis and controlled measures to be activated or scheduled.

A reduction in battery maintenance costs through enhanced charge control and balance and improved testing and ongoing monitoring. With the Satellite UPS System linked to GuardIAN RCM, monitoring each cell in the battery stack maintains a healthy battery state of charge.

Safer Uninterruptible Power Supply Battery Replacement

A compact and portable design enables the Satellite UPS to be brought to the surface for maintenance or battery change-out. Reinforced sliding draws house the batteries and allows for a top-down installation and removal process; ensuring a safer lifting technique is employed and reducing the risk of injury during battery replacement.