Carbon monoxide in sealed environments can be extremely hazardous to all personnel. An emergency refuge chamber is equipped with different technologies to monitor carbon monoxide levels and remove the harmful gas to maintain a safe, breathable atmosphere.

What is Carbon Monoxide?

Carbon Monoxide (CO) is a colourless, odourless, and tasteless gas that is slightly less dense than air. If encountered in concentrations above 35ppm, it is highly toxic to humans and animals.

The most common CO poisoning symptoms include headaches, vomiting, dizziness, confusion, disorientation, visual disturbance, fainting, and seizures, to name a few. CO poisoning is the most common type of fatal air poisoning.

Inhaled CO combines with haemoglobin which becomes ineffective at delivering oxygen around the body. Oxygen levels are displaced in the blood, causing vital organs to starve and, therefore, causing people to suffocate and lose consciousness.

Monitoring Carbon Monoxide in a Refuge Chamber

Monitoring systems within a MineARC Refuge Chamber can detect and divert compromised air from entering through the Compressed Air Management System, while fixed gas monitoring detects changes in gas concentration inside the chamber and prompts occupants to take corrective action.

Toxicity Monitoring Gas Entering the Emergency Refuge

In the event of an emergency like an underground fire, CO can enter a refuge chamber through various scenarios, such as:

- When workers seeking shelter open the sealed door and the outside atmosphere moves with them.

- Smoke or gases can be drawn through the compressed (mine) airline if the compressor is near a fire from the compressor’s compression of smoke.

- Compromised airlines, from fire or other damage, rupture circulating unclean air.

Compressed Air Toxicity Management

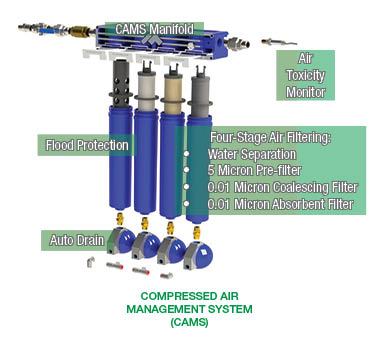

MineARC’s Compressed Air Management System (CAMS) is equipped with a gas toxicity monitor which automatically diverts compromised air.

The monitor activates when oxygen (O2) levels in the airline fall below 19% oxygen in the free air, signifying a fall in the air quality and the presence of smoke, carbon monoxide, or carbon dioxide (CO2).

The gas toxicity monitor activates a solenoid valve at the air intake, which automatically shuts off compressed air. Once activated, the auto shut-off solenoid will remain closed for the remainder of entrapment, ensuring no toxins can enter the chamber through the airline.

A monitor detects compressed smoke bursts, where O2 is displaced dramatically, rather than sampling low-pressure air for slow release contaminants. Meanwhile, gas monitoring within the chamber will determine slow contaminant build-up.

Monitoring CO Inside a Refuge Chamber

Independent gas monitoring within the refuge chamber will determine slow carbon monoxide contaminant build-up. Digital and manual gas monitoring are essential aspects of maintaining a life-supporting atmosphere within an occupied refuge shelter. In addition, closely monitoring gas levels in the chamber allows occupants to take corrective actions to maintain a safe and habitable environment.

Digital Gas Monitoring

Aura-FX Digital Gas Monitoring System (Aura-FX) is a proprietary fixed gas monitoring unit explicitly designed for use in refuge chambers to provide a more convenient solution to internal refuge gas monitoring. Aura-FX measures O2, CO, and CO2 gas concentrations as standard and can monitor up to 11 gases if required individually. It also measures ambient temperature, internal pressure, and relative humidity. All measurements and trends display on a series of user-friendly digital screens. In addition, audible voice alarms will prompt occupants to replace scrubbing chemicals or adjust oxygen supply levels in the refuge chamber as required.

The Aura-FX CO Monitor is an electrochemical gas sensor that measures CO concentration by oxidising it at an electrode and then measuring the resulting current. To reduce cross-sensitivity to other combustible gases, it has chemical filters for Hydrogen Sulfide (H2S), Nitrogen Dioxide (N02), Nitric Oxide (NO) and Sulfur Dioxide (SO2). The CO has an accuracy level of just 4ppm within the reading and a sensor range between 0 and 5,000ppm. Keeping CO levels in the refuge chamber below 30ppm is recommended.

When utilised as a part of the GuardIAN Intelligence network, Aura-FX provides real-time gas monitoring data and analysis of the refuge chamber’s overall internal environment via the GuardIAN Refuge Chamber Monitoring dashboard.

Carbon Monoxide Chemical Scrubbing Inside an Emergency Refuge

In a sealed and occupied refuge chamber during an emergency and the event of compressed air failure or contamination, CO is expelled in low quantities as part of humans’ normal metabolic process. This quantity is higher in smokers and compounded in the enclosed environment of a refuge chamber. It is, therefore, necessary to chemically scrub the air for CO.

Chemical scrubbing is the process of removing gases, such as CO and CO2, from the air. A catalytic process, whereby exothermic chemical reactions change the gas’s composition to water (H2O) and heat, occurs as it passes through the system. Scrubbing systems work in conjunction with active chemicals to ‘scrub’ the build-up of harmful CO and CO2 from the air inside the refuge chamber.

The MineARC Scrubbers use pre-packaged MARCISORB chemical absorber cartridges. MARCISORB CO2 and MARCISORB CO cartridges provide superior scrubbing capacity, efficiency, easy to load, safe to handle and dispose of and store for long periods. Only one CO cartridge is required per portable refuge chamber.

The MARCISORB CO Cartridge is a highly active transition metal oxide catalyst formulated for the oxidisation of contaminants such as CO. Air is passed through the MARCISORB CO Cartridge, converting carbon monoxide into CO2 and H2O. The carbon dioxide produced is then removed by MARCISORB CO2. The cartridges are also effective at eliminating other gases, such as ethylene oxide, hydrogen and methane.